16.698 €incl. VAT 20%

Nr. 58939Güllegrubber- mit 3-Punktanbau- mit Baujahr 2016- mit 4, 5m Arbeitsbreite- mit 2-balkigen Federzinken- mit 17 Stück Federzinken- mit Stufenlo

Premium Gold dealer

Results

16.698 €incl. VAT 20%

Nr. 58939Güllegrubber- mit 3-Punktanbau- mit Baujahr 2016- mit 4, 5m Arbeitsbreite- mit 2-balkigen Federzinken- mit 17 Stück Federzinken- mit Stufenlo

Premium Gold dealer

Price on request

DUPORT Gülle-Schlitzgerätein verschiedenen Ausführungen erhältlich:All Track: leichte Ausführung- hydraulisch angetriebener Verteiler- Arbeitsbreiten

Premium Gold dealer

35.880 €incl. VAT 20%

- Scheibeninjektor 6, 40 m Arbeitsbreite - 30 Abgänge mit 40 mm Durchmesser- 22 cm Scheibenabstand- Dreipunktanbau Kat. 3-Original Harsö Schneidverteiler- W

Perwolf Gülletechnik GmbH

8742 Obdach

Premium Plus dealer

Price on request

== Overige details (NL) ==nr. 2969 Sproeiwagen 4500 ltr met duopomp en sproeikanon en persaansluiting voor continu pompenStaat: Nieuw Fertilization and irri

Aantjes Goudriaan Machinery

2977 LA Goudriaan

1 month online

Price on request

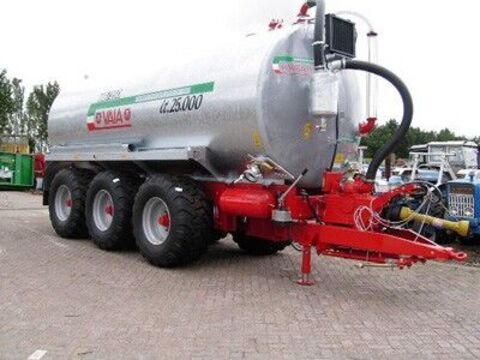

== Overige details (NL) ==Standaard uitgevoerd met:Draaibaar trekoogHydraulische steunpootVerlichting in schommelende units3 Hydraulisch geremde 10-gaats ADR

Aantjes Goudriaan Machinery

2977 LA Goudriaan

1 month online

Price on request

== Overige details (NL) ==Joskin Modul 02 4000MEAan buiten- en binnenzijde gegalvaniseerde tankWielen 385/65R22.5Walterscheid aftakas met 6 groeven4 m PVC zu

Aantjes Goudriaan Machinery

2977 LA Goudriaan

1 month online

Price on request

== Overige details (NL) ==Watertanken met haspelWatertank met inhoud vanaf 2.000 liter Voorzien van vacuümpompHaspel kan handmatig, hydraulisch, elektrisch of

Aantjes Goudriaan Machinery

2977 LA Goudriaan

1 month online

Price on request

== Overige details (NL) ==Vaia MB100 Watertank met uitschuifbare zuigarm • 10.000 liter • Draaibaar trekoog • Hydraulische steunpoot • Zij aansluit

Aantjes Goudriaan Machinery

2977 LA Goudriaan

1 month online

Price on request

== Overige details (NL) ==Standaard uitgevoerd met: • Draaibaar trekoog • Hydraulische steunpoot • Zij aansluiting links, Rechts een blinde flens • G

Aantjes Goudriaan Machinery

2977 LA Goudriaan

1 month online

Price on request

== Overige details (NL) ==Vaia MB 35 watertank standaard uitgevoerd met: • Draaibaar trekoog • Spatborden • Hydraulische steunpoot • Zij aansluiting

Aantjes Goudriaan Machinery

2977 LA Goudriaan

1 month online

Price on request

== Overige details (NL) ==Vaia waterwagen MB32 • Draaibaar trekoog • Hydraulische steunpoot • Zij aansluiting rechts • Luchtgeremd • Banden 500/5

Aantjes Goudriaan Machinery

2977 LA Goudriaan

1 month online

Price on request

== Overige details (NL) ==Vaia waterwagen MB 100 • Inhoud 10.000 liter • Compleet met zuigarm 8'' • Radiografisch bediend • Luchtgeremd met ALR venti

Aantjes Goudriaan Machinery

2977 LA Goudriaan

1 month online

Price on request

== Overige details (NL) ==Joskin waterwagen uit voorraad leverbaar • Inhoud 5000 liter • Aan buiten en binnenzijde gegalvaniseerde tank • Wielen 550/60R

Aantjes Goudriaan Machinery

2977 LA Goudriaan

1 month online

Price on request

== Overige details (NL) ==Waterwagen/ mesttank • Inhoud 6800 liter • Banden 620/55/26.5 • 7000 liter vacuumpomp • Nette tank !

Aantjes Goudriaan Machinery

2977 LA Goudriaan

1 month online

Price on request

== Overige details (NL) ==Waterwagen MB 45 • Tankinhoud 4500 liter • 5000 liter vacuümpomp • Draaibaar trekoog • Inclusief aftakas • Zijaansluitin

Aantjes Goudriaan Machinery

2977 LA Goudriaan

1 month online

Price on request

== Overige details (NL) ==Vaia waterwagen MB32 • Draaibaar trekoog • Hydraulische steunpoot • Zij aansluiting rechts • Banden 15/75/15 • Gegalvani

Aantjes Goudriaan Machinery

2977 LA Goudriaan

1 month online

Price on request

== Overige details (NL) ==Tandamas waterwagen • Inhoud 8000 liter • Banden 80% • Voorzien vacuumpomp • Zo uit het werk Staat

Aantjes Goudriaan Machinery

2977 LA Goudriaan

1 month online

Price on request

== Overige details (NL) ==Enkelas waterwagen • Inhoud 4200 liter • Banden 80% • Voorzien vacuumpomp • Zo uit het werk Staat:

Aantjes Goudriaan Machinery

2977 LA Goudriaan

1 month online

Price on request

== Overige details (NL) ==Waterwagen 5 m3 • Voorzien vacuumpomp • Banden 80% • Voorzien van kenteken • Zo uit het werk Staat

Aantjes Goudriaan Machinery

2977 LA Goudriaan

1 month online

Price on request

== Overige details (NL) ==Standaard uitgevoerd met:Draaibaar trekoogSpatbordenHydraulische steunpootZij aansluiting links, rechts een blinde flensGeremde AD

Aantjes Goudriaan Machinery

2977 LA Goudriaan

1 month online

6.800 €

== Mer informasjon (NO) ==mascus_category: agridrillsPlease provide reference number upon request: 6669See en.landbrukssalg.no/6669 for more imagesSpecificati

Landbrukssalg.no AS

7080 H Trondheim – Tromsø

Premium Plus dealer

32.400 €

== Mer informasjon (NO) ==mascus_category: tillageequipmentmerke: GarciaPlease provide reference number upon request: 6585See en.landbrukssalg.no/6585 for mor

Landbrukssalg.no AS

7080 H Trondheim – Tromsø

Premium Plus dealer

19.600 €

== Mer informasjon (NO) ==mascus_category: agridrillsPlease provide reference number upon request: 6387See en.landbrukssalg.no/6387 for more imagesSpecificati

Landbrukssalg.no AS

7080 H Trondheim – Tromsø

Premium Plus dealer

Price on request

== Overige details (NL) ==4 Verdeler 48 pijps systeem Baars met nieuwe hydro motor - beluchters en overdruk beveiliging.Staat: Nieuw Fertilization and irrig

Aantjes Goudriaan Machinery

2977 LA Goudriaan

2 months online

1.500 €

== Mer informasjon (NO) ==mascus_category: agridrillsmerke: DOFFPlease provide reference number upon request: 6330See en.landbrukssalg.no/6330 for more images

Landbrukssalg.no AS

7080 H Trondheim – Tromsø

Premium Plus dealer

1.400 €

== Mer informasjon (NO) ==mascus_category: agridrillsmerke: DOFFPlease provide reference number upon request: 6294See en.landbrukssalg.no/6294 for more images

Landbrukssalg.no AS

7080 H Trondheim – Tromsø

Premium Plus dealer

27.300 €

== Mer informasjon (NO) ==mascus_category: agridrillsmerke: GarciaPlease provide reference number upon request: 6274See en.landbrukssalg.no/6274 for more imag

Landbrukssalg.no AS

7080 H Trondheim – Tromsø

Premium Plus dealer

4.800 €

== Mer informasjon (NO) ==mascus_category: agridrillsmerke: DOFFPlease provide reference number upon request: 6221See en.landbrukssalg.no/6221 for more images

Landbrukssalg.no AS

7080 H Trondheim – Tromsø

Premium Plus dealer

4.300 €

== Mer informasjon (NO) ==mascus_category: agridrillsmerke: HøgborgPlease provide reference number upon request: 6100See en.landbrukssalg.no/6100 for more ima

Landbrukssalg.no AS

7080 H Trondheim – Tromsø

Premium Plus dealer

1.300 €

== Mer informasjon (NO) ==mascus_category: agridrillsmerke: DOFFPlease provide reference number upon request: 5870See en.landbrukssalg.no/5870 for more images

Landbrukssalg.no AS

7080 H Trondheim – Tromsø

Premium Plus dealer

Price on request

== Overige details (NL) ==prijs: Prijs op aanvraagQuantity: 1Unit: StukVeenhuis Fullject3 of 4 punts aanspanning geschroefdHydraulisch inklapbaarmet transp

Kraakman Perfors B.V.

1775 T Middenmeer

Premium Plus dealer

25.800 €

== Mer informasjon (NO) ==mascus_category: agridrillsPlease provide reference number upon request: 5544See en.landbrukssalg.no/5544 for more imagesSpecificati

Landbrukssalg.no AS

7080 H Trondheim – Tromsø

Premium Plus dealer

59.400 €

== Mer informasjon (NO) ==mascus_category: agridrillsPlease provide reference number upon request: 5523See en.landbrukssalg.no/5523 for more imagesSpecificati

Landbrukssalg.no AS

7080 H Trondheim – Tromsø

Premium Plus dealer

Price on request

== Overige details (NL) ==prijs: Prijs op aanvraagQuantity: 1Unit: StukNette Schuitemaker exacta 870Werkbreedte 8, 7mFasterCentraal smeersysteemVogelenzang

Kraakman Perfors B.V.

1775 T Middenmeer

Premium Plus dealer

77.945 €incl. VAT 19%

________TBL Scheibeninjektor, 13, 5m Arbeitsbreite mit dicken ScheibenRahmen:Scherenklappsystem mit Tragarm auf 9m Arbeitsbreite, geringes EigengewichtSynchrone

LVD - Bernard Krone GmbH

48480 Spelle

17-07-2025 04:21

== Mer informasjon (NO) ==mascus_category: agridrillsPlease provide reference number upon request: 1518See en.landbrukssalg.no/1518 for more imagesDescription

Landbrukssalg.no AS

7080 H Trondheim – Tromsø

Premium Plus dealer

Price on request

== Overige details (NL) ==Jako tank • Inhoud 8000 liter • Voorzien van vacuumpomp Staat: Gebruikt Fertilization and irrigation

Aantjes Goudriaan Machinery

2977 LA Goudriaan

03-07-2025 07:35

Price on request

== Overige details (NL) ==Vaia MB100 watertank met 8'' zuigarm • Tank inhoud 10.000 liter • Banden 550/60x22.5 • Draaibaar trekoog • Hydraulische ste

Aantjes Goudriaan Machinery

2977 LA Goudriaan

27-06-2025 08:02

81.991 €incl. VAT 19%

________Fahrwerk, hydr. klappbar, Beleuchtung, DL Bremse, 8 Reihen, 75cm, Stützräder, hinten 3 Punktaufhängung Fertilization and irrigation equipment Liquid manure

MERKANTIL Export-Import GmbH

17094 Pragsdorf

25-04-2025 04:02

23.681 €incl. VAT 19%

________Güllescheibenegge, 5, 00 m Arbeitsbreite, hydr. klappbar, Nachläufer: Rohrstabwalze, mit:Vogelsang DosiMat, Baujahr: 2018, Fertilization and irrigation equi

LVD - Bernard Krone GmbH

48480 Spelle

05-04-2025 04:19

Price on request

== Overige details (NL) ==prijs: Prijs op aanvraagQuantity: 1Veenhuis VMA 5.70 bouwlandbemester Fertilization and irrigation equipment Liquid manure inject

Kraakman Perfors B.V.

1775 T Middenmeer

Premium Plus dealer

17.731 €incl. VAT 19%

________Haupteinsatz war Grünland - ca. 450 ha im Einsatz gewesen - sofort einsatzbereit - Schare und Auslaufgummis in 2024 komplett erneuert - ein

Gruber Agrartechnik GmbH.

04319 Leipzig -Engelsdorf

20-02-2025 04:48

20.233,50 €incl. VAT 23%

== Weitere Informationen (DE) ==BeTEC Gülleinjektor HILLYArbeitsbreite: 9 mAbstand zwischen den Schläuchen: 250 mmAnzahl Schläuche: 30 oder 36Durchmess

DC Sp. z o.o.

16-050 Michałowo

Premium Plus dealer

15.362,70 €incl. VAT 23%

== Weitere Informationen (DE) ==BeTEC Gülleverteiler- Arbeitsbreite: 6 m - Abstand zwischen den Verteilern: 250 mm - Anzahl der Schläuche: 24- Durchmes

DC Sp. z o.o.

16-050 Michałowo

Premium Plus dealer

87.670,71 €incl. VAT 23%

== Weitere Informationen (DE) ==Spawex Gülletankwagen WA-22 000Gesamtabmessungen: - Länge mit Spritzwand: 10 050 mm- Länge ohne Schwallwasseranlage: 9250

DC Sp. z o.o.

16-050 Michałowo

Premium Plus dealer

55.086,78 €incl. VAT 23%

== Weitere Informationen (DE) ==Marco-Polo Güllewagen MPR-2S/20000Serienausstattung:Fahrgestell / Aufbau:RahmenbauweiseZugöse D-50 verschraubtSta

DC Sp. z o.o.

16-050 Michałowo

Premium Plus dealer

38.779,44 €incl. VAT 23%

== Weitere Informationen (DE) ==Marco-Polo Gülletankwagen MPR-2S/12000Fahrgestell:Selbsttragende KonstruktionZugöse D-50, verschraubtStarre Metall-De

DC Sp. z o.o.

16-050 Michałowo

Premium Plus dealer

77.000 €VAT not applicable

== Overige details (NL) ==prijs: Prijs op aanvraagQuantity: 1Unit: StukLicense Plate: LBG-74-RINHOUD 22.000 LITERWEGEN EN MONSTERENTANDEMSTEL MET BLADVERIN

Kraakman Perfors B.V.

1775 T Middenmeer

Premium Plus dealer

Hit 1 - 48 from 64 (Page 1 from 2)

Slurry injectors play a crucial role in modern agriculture, particularly with regard to the sustainable use of nutrients. They ensure that liquid manure is injected directly into the soil in a precise and environmentally friendly manner, which increases nutrient efficiency while minimizing ammonia losses and unpleasant odours. Spreading the slurry close to the ground also makes it easier to comply with environmental regulations, which is particularly beneficial for farmers in regions with strict environmental regulations.

A key benefit of slurry injectors is the reduction of emissions. By injecting the slurry directly into the soil, harmful ammonia emissions are significantly reduced. This not only protects the environment, but also ensures that important nutrients such as nitrogen can be used more efficiently. For livestock farms or mixed farms that use liquid manure as fertilizer, this is a sustainable solution that makes both ecological and economic sense.